Our Markets

Automotive

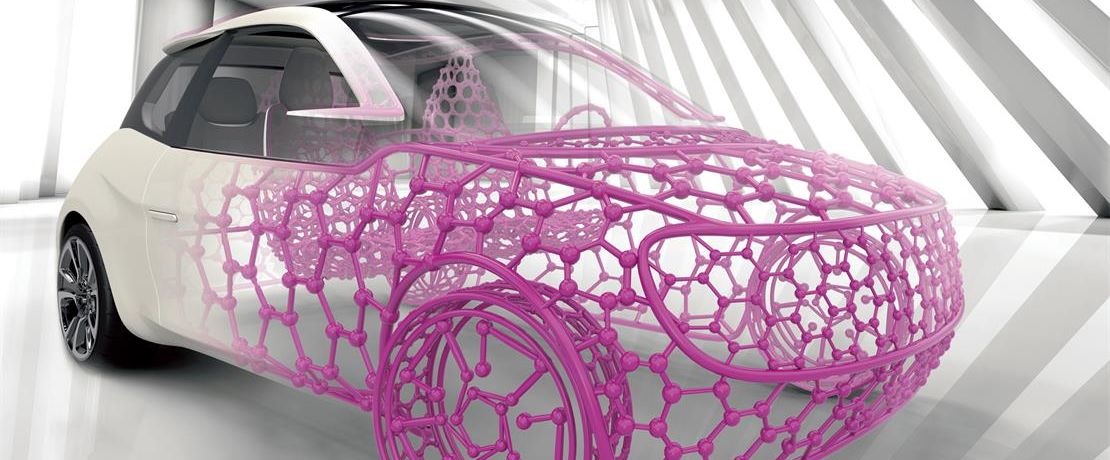

Hit the road. Innovative products from Evonik make cars lighter as well as more environmentally friendly and economical - thanks to the company's light structural foams, special plastics applications, and adhesives.

When used in automobile body parts in the roof, trunk lid or hood, sandwich elements with products from Evonik reduce the weight by 60 to 70 percent compared to conventional steel parts. Fillers for tire rubber reduce rolling resistance and therefore fuel consumption - an energy-efficient and environmentally friendly solution that also saves money.

Consistently high product quality, on-time delivery, excellent service and innovative solutions have helped the polyamide molding compounds from Evonik take a leading position in automotive applications such as fuel lines and vacuum brake booster lines.

Monomers from Evonik are used to impregnate cast metal engine parts. This guarantees a seal against combustion gases and engine fluids, improves the mechanical stability of the parts, protects them against corrosion and, ultimately, prolongs service life.

When car drivers see red, Evonik is to thank once again. Taillights are made from special PMMA molding compounds, which give them impressive properties such as excellent colorfastness and outstanding weather resistance. Transparent PMMA for automotive glazing also reduces weight by 40 to 50 percent compared to conventional glass. Apart from the lower weight, it is especially the excellent transparency, the very good weather resistance, the pleasant acoustics and the outstanding formability of the material that open up many new design options.

Whether it is for applications such as windshield bonding, lamination in the car interior, sound damping mats or underbody protection, a universal plasticizer from Evonik ensures optimum flow properties of adhesives and sealing compounds and also the required flexibility of vibration and protective compounds even at low temperatures, thus making an important contribution towards reducing weight in automobile construction. In addition, fumed silica enhances the rheological and mechanical properties of adhesives and sealants and organofunctional silanes are used as adhesion promoter in adhesives and sealants.

Many automobile components, such as the steering wheel, the gear lever knob and the window lifter are subject to stress every day. Through their high abrasion resistance, the coatings from Evonik are ideally suited, not only to refine such components, but also to protect them against the ravages of time.

Improved seating comfort and lower noise level inside the automobile create a pleasant atmosphere for drivers and their passengers. As essential additives for the production of many different polyurethane foam applications in the automotive industry, polyurethane additives from Evonik add to the comfort and general wellbeing of drivers and passengers. In foam production, the products from Evonik ensure a suitable cell structure balancing foam rebound and shrinkage. This not only improves the sound-absorbing properties of the headliner and the foot mats, but also the elasticity of the automobile seats. Adhesives and sealing compounds based on Evonik products also provide a high degree of soundproofing and keep the unpleasant hum of the engine under the hood.

An additive manufactured by Evonik that is added to plastics in very small amounts helps protect door and side panels against scratches. The unsightly white scratches that one often found on the car door are now a thing of the past.