Our Markets

Pulp, Paper, and Packaging

New, modern packaging materials offer virtually unlimited possibilities when it comes to design and functionality. In times where many products are similar, their visual impact becomes increasingly important.

Evonik turns packaging into a real eye catcher: Special bonding agents are used in paints and printing inks and make a significant contribution in the printing of labels and packaging. Others protect against corrosion, wear, and scratches. Renewable raw materials, such as rapeseed and sugar, are increasingly used in the development and manufacture of these products.

UV-hardened silicone release coatings from Evonik ensure that self-adhesive products can be removed from their packaging without any problem, such as feminine hygiene products from their packaging foil.

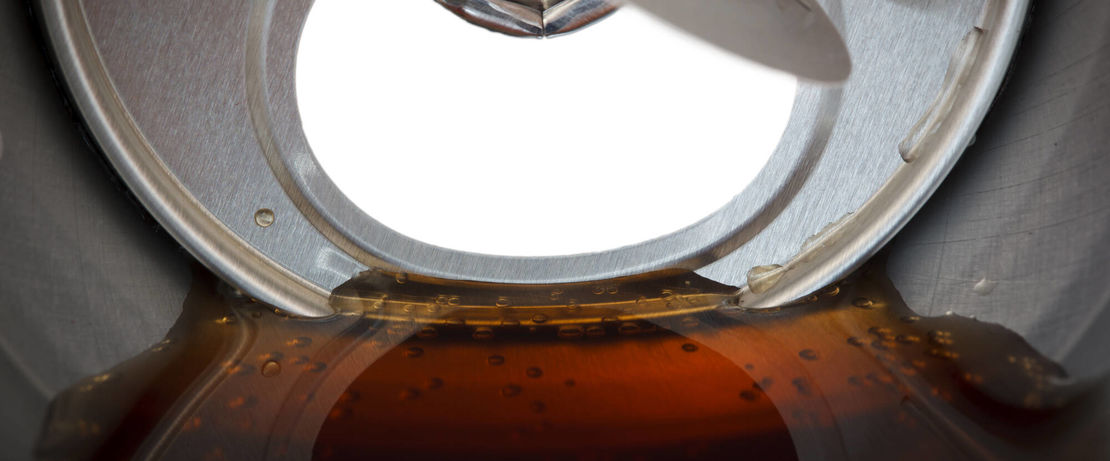

Recycled paper is an important raw material for paper. With products and solutions from Evonik, printing inks are separated from the recycled paper, allowing a valuable paper-making fiber to be recovered. And in paper production, additives from Evonik in defoaming agents guarantee a smooth production process.

Optical brightener additives (OBA) are needed to increase the whiteness of paper (also recycled paper) in a resource conserving manner. Cyanuric chloride is one of the most important raw materials used in the production of OBAs.

Before pulp becomes high quality printing paper, it has to be coated. Products from Evonik help ensure that the coating is evenly spread and that the process is carried out quickly. Evonik`s fumed silica and precipitated silica enable and enhance papers for modern printing techniques. Silica improve ink jet printability in terms of instant dry times as well as excellent color gamut and image resolution. The result is paper that is extremely suitable for magazines and periodicals.

Fluff pulp is used in a couple of different applications in the consumer market. These range from products used for personal hygiene to wipers or pads used in medical and food handling. Even in applications where superabsorbents are used, the presence of fluff pulp is necessary in order to facilitate the transport of fluids to the superabsorbents. Different additives are used to adjust the overall-performance of the fluff pulp/tissue. Whether wet end and/or topical additivation is suitable mainly depends on the fiber types and fiber quality. Our unique set of additives are either based on organic chemistry or on organomodified siloxanes (OMS) which enables us to offer additives which exactly meet the requirements of producers of fluff pulp or tissue.